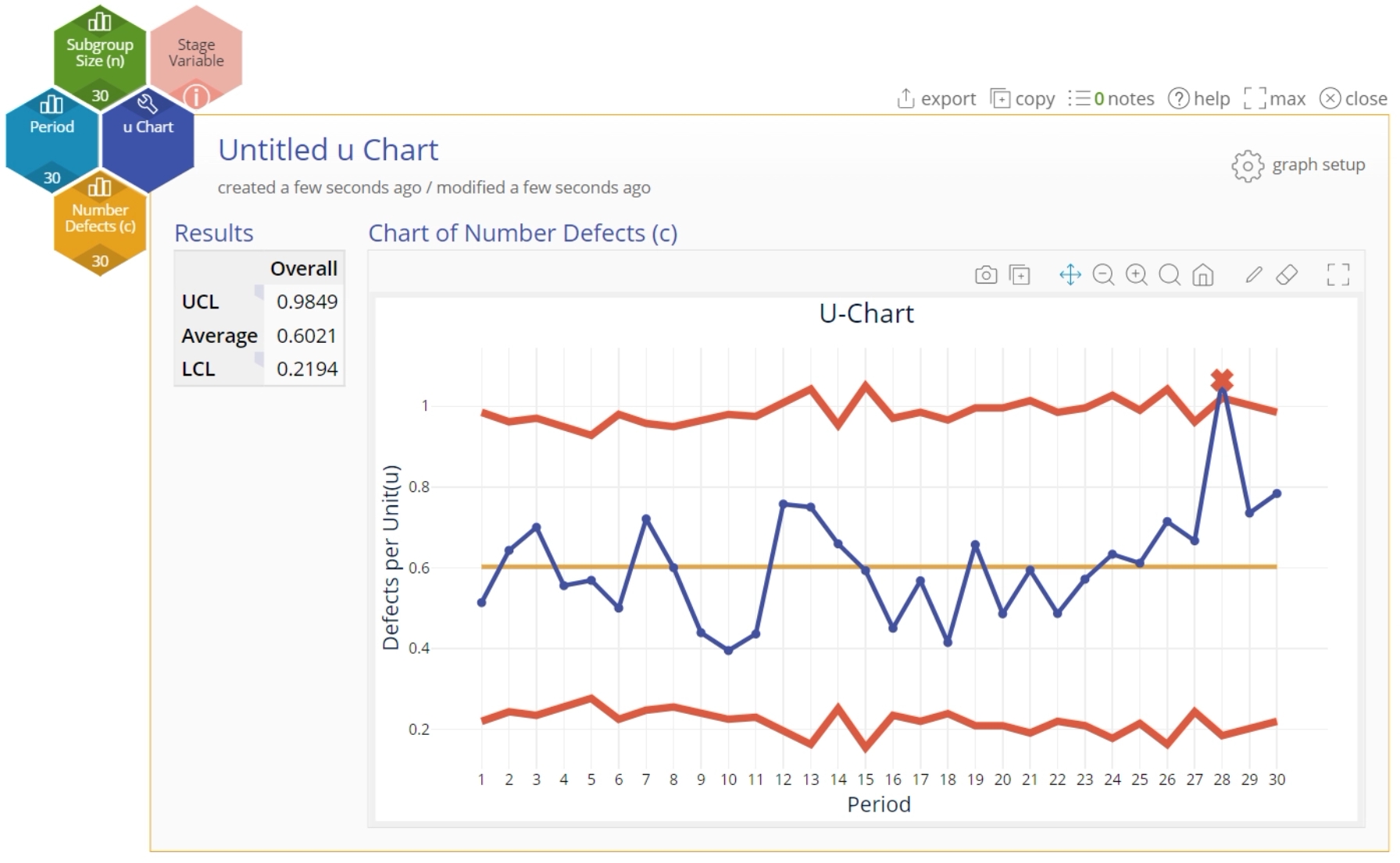

U Chart Example Assessment Overview

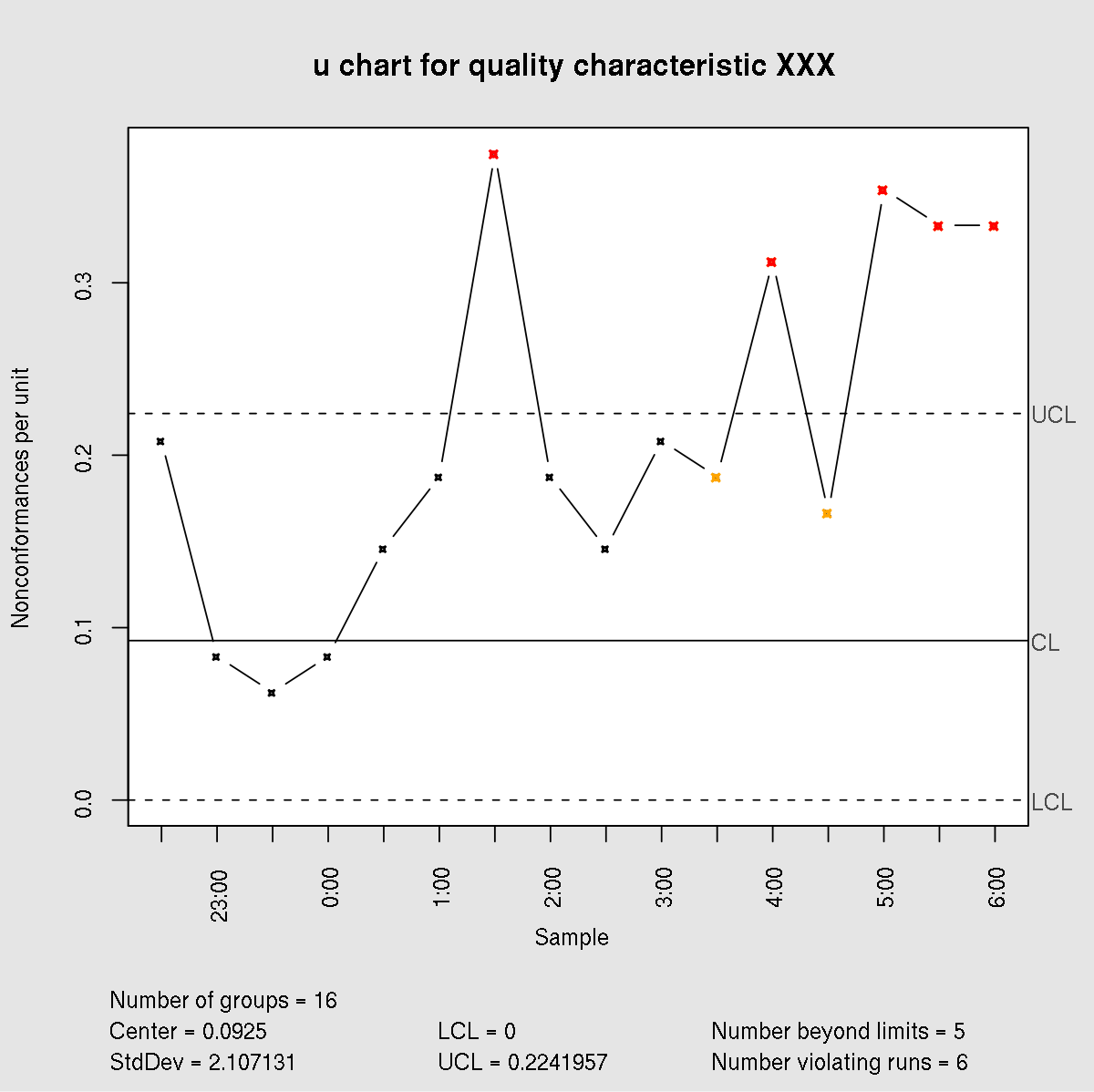

u chart example. There are five main benefits of using a u chart to visualize quality control data: Monitors the average number of nonconformities or defects per unit when dealing with varying sample sizes or.

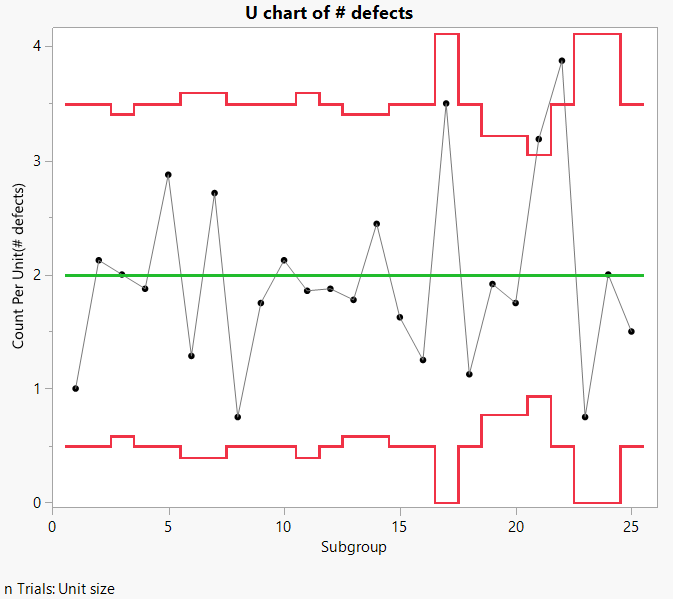

u chart example There are five main benefits of using a u chart to visualize quality control data: They help quality control managers understand inherent variations. Because the sample sizes are not equal across subgroups, the limits are uneven.

Two Of The Last Five Samples Are Not Within The Control Limits.

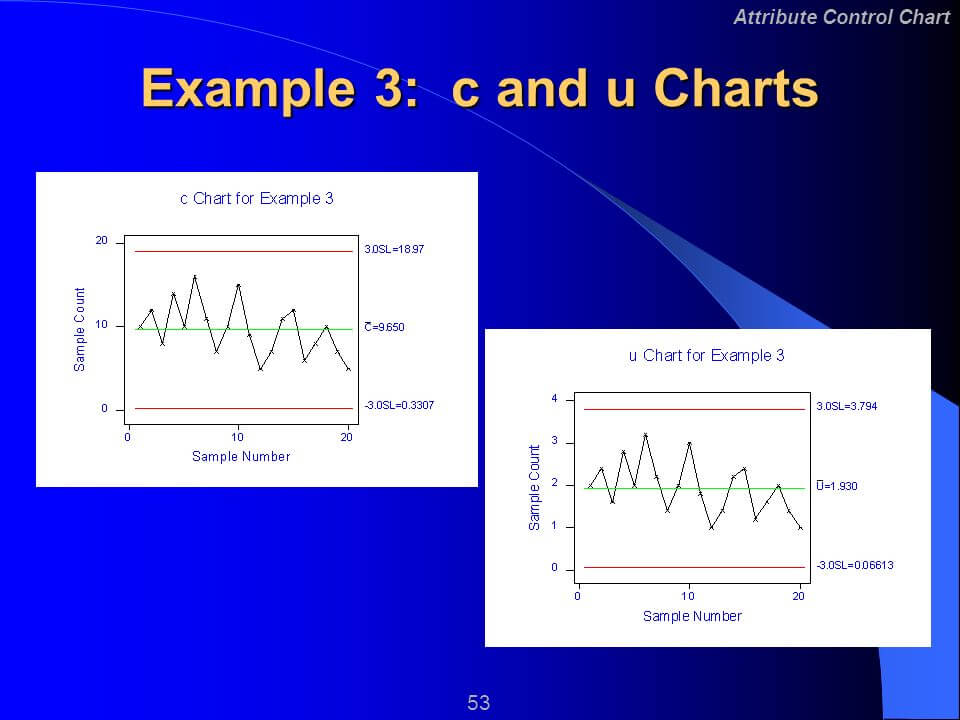

A specific type of control chart, the u chart, or defects per unit chart, is instrumental in situations where the monitoring of defects per. A u chart is a type of attribute control chart used to control the mean number of defects in samples of differing sizes taken from a process. They help quality control managers understand inherent variations.

The Following Data Shows The Number Of Defects Per Lot In 20.

There are five main benefits of using a u chart to visualize quality control data: Putting defect data on a u chart helps quality control managers and production engineers quickly see changes in how many defects occur in a sample. Monitors the average number of nonconformities or defects per unit when dealing with varying sample sizes or.

Because The Sample Sizes Are Not Equal Across Subgroups, The Limits Are Uneven.

Example of using a u chart in a six sigma project (constant sample size) example:

Leave a Reply